boost WAREHOUSE PICKING Efficiency

work smarter. move faster.

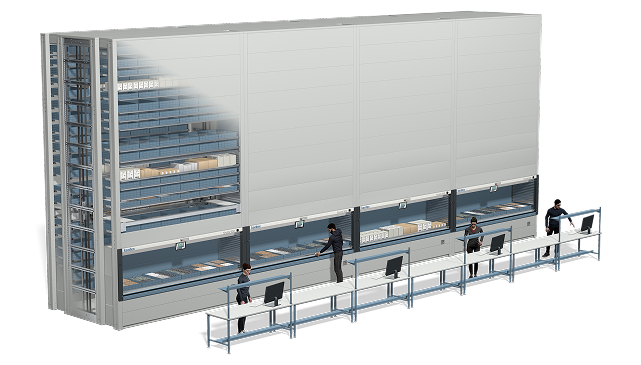

AMH helps you increase warehouse picking efficiency with high-density, goods-to-person systems like vertical lift modules, horizontal carousels, and pick-to-light technology. Reduce walking time, optimize labor, and improve throughput across your facility.

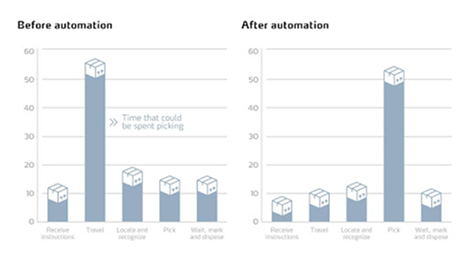

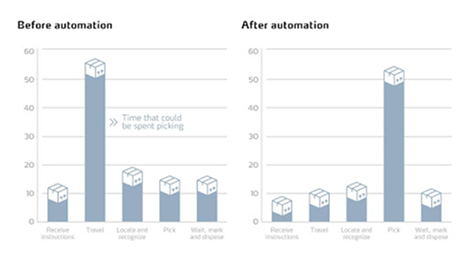

Eliminate time-wasting tasks

Manual storage and retrieval systems often create hidden inefficiencies. Time is lost in travel, searching, and inefficient workflows.

At AMH, we help you eliminate those bottlenecks, improving order picking speed, reducing errors, and maximizing your warehouse labor efficiency.

Automation improves your picking workflow by:

- Reducing walk and search time by up to 80%

- Increasing pick rates up to 4x over traditional shelving

- Bringing items directly to the operator with goods-to-person systems

Faster access.

Smarter movement.

Less labor wasted.

Scalable efficiency that grows with you

Efficiency isn’t just about speed—it’s about control, consistency, and long-term gains.

Our solutions are ideal for:

- Batch picking and high-volume fulfillment

- Parts kitting and assembly support

- Multi-shift or 24/7 operations with minimal downtime

All while tracking every action for easy audits and quality control.

System Integration That Speeds Everything Up

Our experts help you go beyond hardware with full-service support:

- Seamless integration with your WMS or ERP

- Workflow design that removes friction and lag

- Ongoing training, maintenance, and optimization

When systems talk to each other—and work together—you get measurable results fast.

Case Study

Miller Industries 6X More Picking Productivity

Client:

Miller Industries

Industry:

Manufacturing / Industrial Equipment

Solution:

Vertical Lift Module (VLM) ASRS with Oracle Integration

Focus:

Maintenance, Repair, and Operations (MRO) Parts Management

Miller Industries, a leader in towing and recovery equipment, faced inefficiencies with manual picking from high-bay racks using forklifts and carts. This caused slow accessibility, inventory damage, and was limiting growth.

The Solution

- Installed 8 Kardex Shuttle XP Vertical Lift Modules (VLMs) to store small parts closer to production

- Integrated Kardex Power Pick Global software with their warehouse management system for paperless, automated picking

Results

- Picks per man-hour jumped from 20 to 120—a 6X increase in productivity

- Saved $607,349 annually in labor costs

- Achieved 99.8% picking accuracy

- Freed up over 4,800 sq ft of floor space

- Avoided a $2.2 million warehouse expansion

“

Automation transformed our workflow. We are faster, more accurate, and able to meet growing demand without adding labor.

Boost Throughput Without Adding Headcount

You don’t need more workers. You need a system that works better.

Many AMH clients see a 2–3x increase in picking efficiency with the right automation strategy—no additional staff required.