Vertical lift modules (vlms)

Maximize Space.

Boost Accuracy.

Increase Throughput.

Vertical Lift Modules (VLMs) are high-density, automated storage and retrieval systems designed to help operations reclaim up to 85% of floor space while significantly improving picking speed, accuracy, and productivity.

Using a “goods-to-person” approach, VLMs bring the right part directly to the operator—eliminating wasted travel time and manual searching.

IDEAL FOR PARTS OPERATIONS

Whether you’re managing a wide variety of part sizes or looking to streamline order picking, VLMs offer unmatched flexibility.

They’re perfect for:

- Maintenance & spare parts storage

- Order fulfillment

- Tool cribs & MRO operations

- Manufacturing workstations

VLMs can be seamlessly integrated with barcode scanners, conveyors, lifting aids, and robotics—creating a fully automated, high-efficiency workflow.

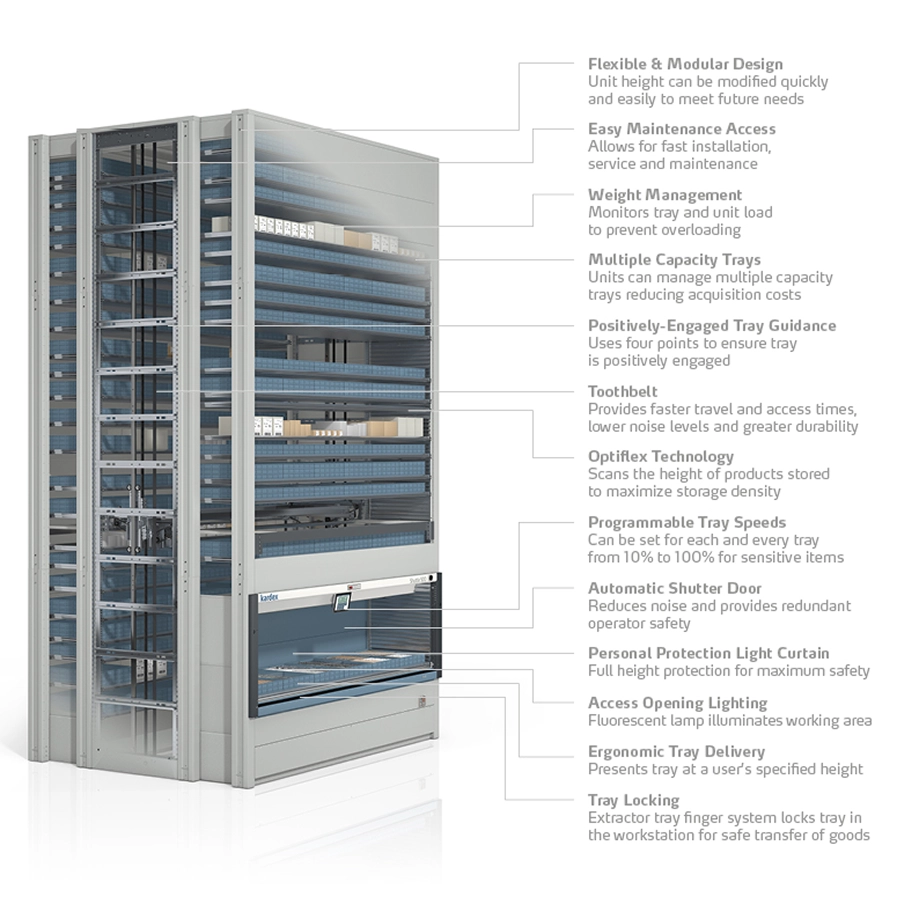

The Kardex shuttle:

A FLEXIBLE, EFFICIENT STORAGE STRATEGY

Kardex Shuttle VLMs feature a modular design that adapts to virtually any facility layout:

- Increases in height by 3.9-inch (100 mm) increments to match various ceiling heights

- Can be relocated and reconfigured by adding or removing modules as needs change

- Supports up to 6 access openings on the front or rear—ideal for multi-floor installations

- Access openings can be repositioned later, offering long-term flexibility

- Built-in shutter doors enhance operator safety and protect stored items from dust and airflow

This versatility ensures that your storage solution evolves with your operation—whether you're scaling up, relocating, or optimizing across departments.

HOW VLMS WORK

The Kardex Shuttle system stores trays in front and rear columns, with a central extractor that automatically retrieves and delivers trays to an ergonomic access point via barcode scan or touchscreen input.

Key features include:

- Cubestar technology that dynamically scans tray height for maximum space efficiency

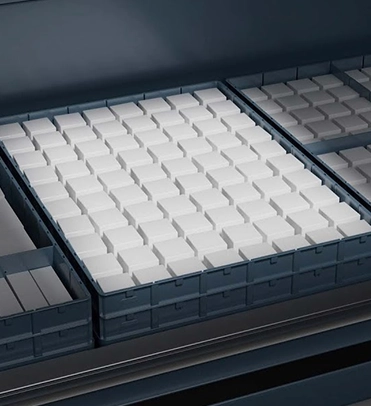

- 1-inch (25 mm) storage resolution for high-density organization

- Modular construction to fit almost any ceiling height or building layout

- Enclosed system to reduce dust exposure and protect stored materials

SMART STORAGE FOR SMART OPERATIONS

VLMs deliver measurable results—more floor space, faster picks, and fewer errors. Whether used for MRO, production parts, or fulfillment, they provide a scalable, high-performance solution for modern material handling.