Improve Warehouse picking Accuracy

Pick It Right the First Time

Discover how AMH’s automation solutions improve warehouse picking accuracy and reduce picking and shipping errors. Boost productivity and customer satisfaction with barcode verification, ASRS, and WMS integration.

Why Accuracy Matters

Every misspick costs you time, money, trust, and customer satisfaction. In high-volume operations, even a 1% error rate adds up fast.

Automated solutions—including vertical lift modules, automated storage and retrieval systems (ASRS), and barcode scanning—are designed to enhance warehouse picking accuracy at every step of fulfillment.

With AMH systems, you can:

- Achieve 99.9% pick accuracy

- Minimize returns, rework, and shrink

- Improve operator performance with guided workflows

Built-In Intelligence

Kardex systems use:

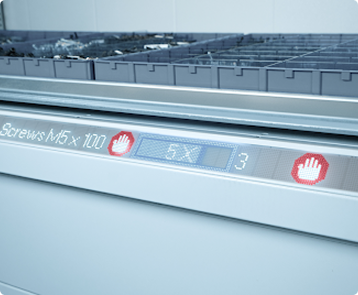

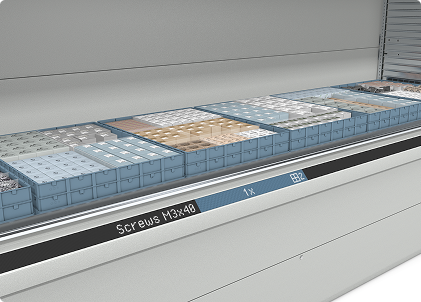

- Light-directed picking to reduce cognitive load

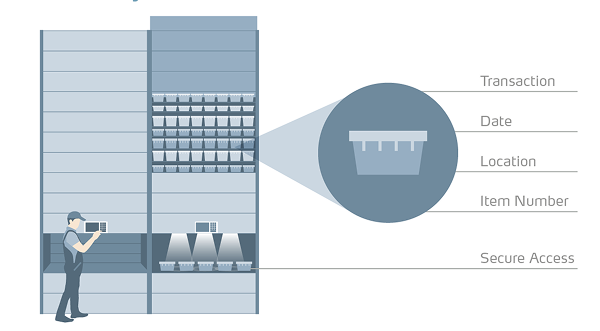

- Barcode scanning & confirmation to ensure order integrity

- Controlled inventory access to prevent unauthorized or mistaken pick

All while tracking every action for easy audits and quality control.

Case Study

FLOWSERVE - Gaining Control, Accuracy & Efficiency in MRO Inventory

Client:

Flowserve

Industry:

Manufacturing / Industrial Equipment

Solution:

Vertical Lift Module (VLM) ASRS with Oracle Integration

Focus:

Production Parts

Case Study

Flowserve was facing major inefficiencies in their maintenance parts storage. MRO picking Operations, inventory was stored manually in bins and boxes scattered across racking and shelving—without any inventory software. The lack of control and traceability led to frequent part loss, damage, and costly production downtime.

Project Goals

- Reclaim floor space for production parts

- Improve inventory accuracy and visibility

- Reduce picking times and search efforts

- Streamline MRO operations with software integration

The Solution

Flowserve implemented two 21-foot Vertical Lift Modules (VLMs) to condense their MRO parts into just 200 sq ft. We integrated Kardex Power Pick Global (PPG) with their Oracle ERP, eliminating manual tracking and dramatically improving control over inventory.

Results

- 75% Reduction in picking time – from 12 minutes to 3 minutes per job

- 1,500+ Hours Saved Annually searching for materials

- 70% Reduction in inventory write-offs due to improved accuracy

- Significant Floor Space Recovered for production operations

Continued Growth

Impressed with the ROI, Flowserve has expanded their investment—ordering three additional shuttles to manage production parts with the same accuracy and efficiency.

Key Takeaway

Impressed with the ROI, Flowserve has expanded their investment—ordering three additional shuttles to manage production parts with the same accuracy and efficiency.