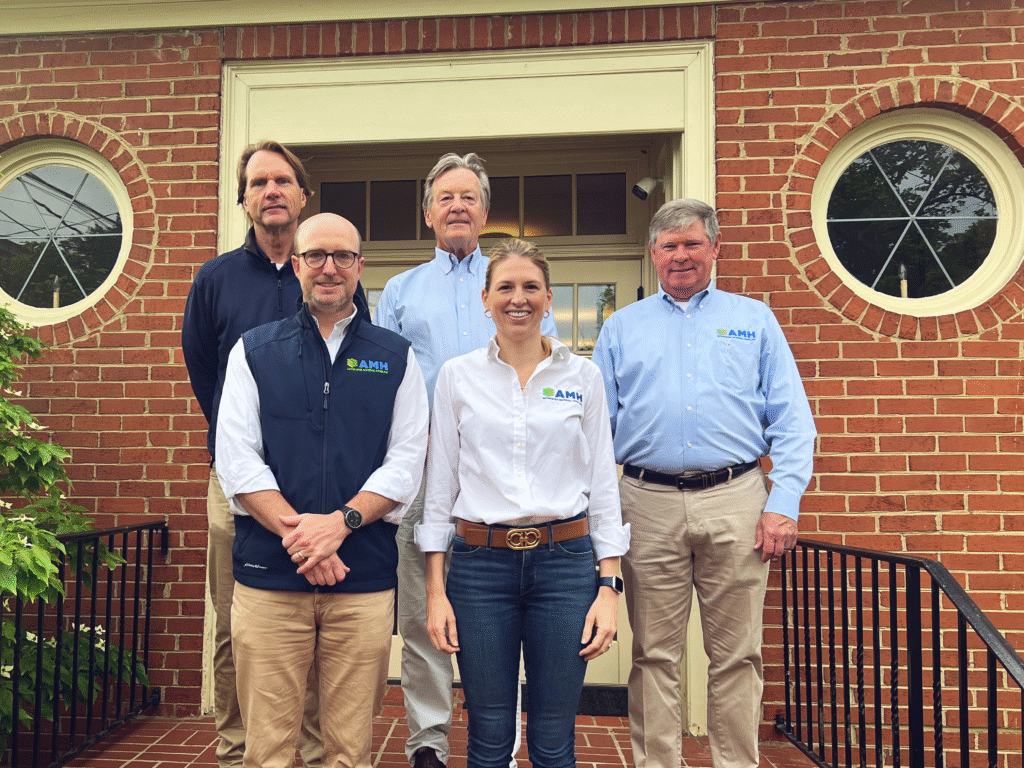

meet the amh team

engineering custom, efficient storage solutions since 1977.

Automated Material Handling:

Your Facility at Peak Efficiency

ESTD

1977

Since 1977, Automated Material Handling has been solving complex space, efficiency, and control challenges with a relentless focus on optimization. From the very beginning, we’ve believed that there’s never just one “right” way to use a space—only the solution that’s right for your business.

Every facility we work with is treated as a unique environment and a work in progress. As your goals evolve and new opportunities for automation arise, we’re here to help you adapt, optimize, and stay ahead.

What sets us apart isn’t just our expertise, it’s our mindset: custom, continuous improvement should never stop.

Our team is passionate about helping companies reach peak performance by designing solutions that align with your space, constraints, and goals.

This commitment to custom service forms the bedrock of AMH’s company culture and the reason so many of our clients become long-term partners. Year after year, many of the world’s largest companies return to AMH to stay competitive, efficient, and ready for what’s next.

want to discover your facility's automation opportunities?

Schedule a free consultation and strategy call with one of our experts today.

AMH CUSTOMER PROJECTS

Flowserve

Linkbelt

Thompson Machinery

Unipres

Miller

Join the Legendary Companies Who Rely on AMH for Maximum Efficiency

Customer Reviews

“

“

“

“

We shoot for 30% ROI and I don’t see why we won’t be able to pull that off. Our customer service level has increased considerably, especially since we got the Kardex, because we can pick, package and ship much faster than we could before. So, our overall customer satisfaction is up, too.

“

“

Make sure you take into account the shop floor inventory transactions that are going to have to take place—just the sheer volume of forklift moves to get a spot cleared out and the next piece of equipment up, and then back into that piece of equipment and up.

“

“

Don’t let the price scare you. It’s a lot cheaper to fill up your cubic feet than it is to purchase new square footage. It’s still cheaper than buying a building or making a building

“

“

We were looking, at the time, at upwards of 116 part numbers that we needed to manage, and a floor

space of about 7,300 square feet. And main body wire harnesses are very, very large, and very, very heavy components that take up a lot of space. So, that number of parts wasn’t going to fit in that small floor space.

“

“

…over the course of two weeks, we got all the components assembled and got the VLMs built. We had four towers. And then the next week after that, Kardex sent a representative who helped us program the system, get all the parts loaded into it, and train up the operators and some of the engineers and salaried employees in the plant as well, so we can help with any sort of downtime issues.

“

“

The AMH team was easy to work with, very attentive. Like any other company, ours has its own little intricacies you need to learn to be successful—but they were more than willing to take on those lessons. Definitely highly rated among the other vendors that I’ve worked with. They were easy to work with on things like changing the POs and doing amendments to the purchase orders.

Tom Jameson

Founder & CEO

Chuck Hawkins

Founder & CEO

Tom Jameson

Founder & CEO